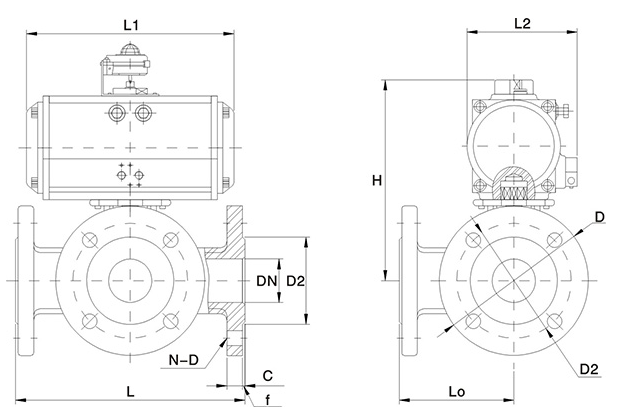

Pneumatic three-way ball valve

Product model: Q644F/Q645F

Nominal diameter: DN15~200mm

Nominal pressure: PN16, 25bar

Connection form: flange

Medium temperature: W1: -40~180°C W2:-40~300°C W3:-30~425°C W4:-40~425°C

Body material: WCB, ZG1Cr18Ni9Ti, ZG0Cr18Ni12Mo2Ti

Applicable medium: water, steam, oil, nitric acid, acetic acid

Product description

Pneumatic three-way ball valve is a three-channel rotary ball valve, which is used for medium diversion, confluence and flow direction switching. Any pipe can be used as an inlet or outlet. There are two types of pneumatic three-way L-type ball valve and pneumatic three-way T-type ball valve, which can meet different industrial requirements. The three-way L-type ball valve cuts off two of the three pipelines, and the three-way T-type ball valve realizes the confluence and diversion of the three connecting pipelines. Widely used in chemical industry, petroleum, light textile, electric power, food and pharmaceutical, refrigeration and paper making and other fields.

Product Features

1. The fluid resistance is small, and its resistance coefficient is equal to the pipe section of the same length.

2. Simple structure, small size and light weight.

3. Tight and reliable, at present, the sealing surface material of ball valve is widely used in plastic, good sealing, and has been widely used in vacuum systems.

4. It is easy to operate and open and close quickly. It only needs to rotate 90° from fully open to fully closed, which is convenient for long-distance control.

5. Easy maintenance, simple structure of ball valve, sealing ring is generally active, disassembly and replacement are more convenient.

6. When fully open or closed, the sealing surface of the ball and the valve seat is isolated from the medium, and when the medium passes, it will not cause the erosion of the sealing surface of the ball valve.

Executive standard

| Design Basis | GB standard | ANSI standard |

| design standards | GB/12237 | ANSI B16.34 |

| Connecting flange size | GB/9113、JB/T79 | ANSI B16.5 |

| Experiment and test | JB/T9092 | API 598 |

Remarks: The structural length and connection dimensions of the series of ball valves can be designed and manufactured according to customer requirements.

Main technical parameters

| Nominal diameter | DN15~200mm |

| Connection method | Flange |

| cylinder configuration | AT series, GT series and imported actuator series |

| Cylinder form | Double acting, single acting (spring return) |

| Control method | Commutation, diversion |

| Nominal pressure | 16、25bar(If higher pressure is required, please specify when ordering) |

| Air source pressure | Double acting:4~8bar、Single acting:5~8bar |

| Medium temperature | W1:-40~180℃ W2:-40~300℃ W3:-30~425℃ W4:-40~425℃ |

| Ambient temperature | Standard type:-20~80℃ |

| Body material | Carbon steel(C)、Stainless steel(P4、P6) |

| Sealing material | Polytetrafluoroethylene (F), p-polyphenylene (PPL), metal hard seal (H), hard alloy (Y) |

Material of main parts

| Serial number | Part Name | Material | Serial number | Part name | Material | ||||

| C | P4 | P6 | C | P4 | P6 | ||||

| 1 | Right body | WCB | ZG1Gr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | 11 | Bushing | PTFE. Composite bearing | ||

| 2 | Nut | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti | 12 | Gland | WCB | ZG1Gr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 3 | Gasket | PTFE. Graphite Metal Composite Gasket | 13 | Bolt | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti | ||

| 4 | Bolt | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti | 14 | Bolt | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti |

| 5 | Body | WCB | ZG1Gr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | 15 | connection bracket | 1Gr18Ni9Ti | 1Gr18Ni9Ti | 1Gr18Ni9Ti |

| 6 | Seat | PTFE. Nylon. Para polystyrene. Metal hard seal | 16 | Bolt | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti | ||

| 7 | Ball | 1Gr18Ni9Ti | 1Gr18Ni9Ti | 1Cr18Ni12Mo2Ti | 17 | connection sleeve | 35 | 1Gr18Ni9Ti | 1Gr18Ni9Ti |

| 8 | Stem | 1Gr13 | 1Gr18Ni9Ti | 1Cr18Ni12Mo2Ti | 18 | Pneumatic device | Extruded Aluminum Alloy | ||

| 9 | Gasket | PTFE | PTFE | PTFE | 19 | Position indicator | plastic | plastic | plastic |

| 10 | Packing | PTFE.Flexible graphite |

|

||||||

Note: Other special sealing materials or special temperatures can also be designed and manufactured according to customer requirements.

Main Dimensions-PN16(16bar)

| Nominal diameter DN(mm) | Dimensions | Connection size | Actuator model | |||||||||

| L | L0 | L1 | L2 | H | D | D1 | D2 | C | f | N-D | ||

| 15 | 150 | 72 | 141/159 | 71/83 | 204/235 | 95 | 65 | 46 | 14 | 2 | 4-14 | ATD50/ATE63 |

| 20 | 160 | 80 | 159/211 | 83/95 | 240/252 | 105 | 75 | 56 | 16 | 2 | 4-14 | ATD63/ATE75 |

| 25 | 180 | 90 | 211/248 | 95/107 | 257/265 | 115 | 85 | 65 | 16 | 2 | 4-14 | ATD75/ATE88 |

| 32 | 200 | 100 | 211/248 | 95/107 | 277/312 | 140 | 100 | 76 | 18 | 3 | 4-18 | ATD75/ATE88 |

| 40 | 220 | 110 | 248/269 | 107/123 | 292/317 | 150 | 110 | 84 | 18 | 3 | 4-18 | ATD88/ATE100 |

| 50 | 240 | 120 | 248/345 | 107/152 | 325/347 | 165 | 125 | 99 | 20 | 3 | 4-18 | ATD88/ATE125 |

| 65 | 260 | 130 | 315/409 | 141/172 | 357/389 | 185 | 145 | 118 | 20 | 3 | 4-18 | ATD115/ATE145 |

| 80 | 280 | 140 | 345/409 | 152/172 | 368/400 | 200 | 160 | 132 | 20 | 3 | 8-18 | ATD125/ATE145 |

| 100 | 320 | 160 | 409/550 | 172/215 | 410/498 | 220 | 180 | 156 | 22 | 3 | 8-18 | ATD145/ATE160 |

| 125 | 400 | 190 | 438/600 | 187/240 | 470/538 | 250 | 210 | 184 | 22 | 3 | 8-18 | ATD160/ATE210 |

| 150 | 440 | 220 | 550/633 | 215/262 | 556/591 | 285 | 240 | 211 | 24 | 3 | 8-22 | ATD190/ATE240 |

| 200 | 550 | 260 | 600/730 | 210/330 | 648/687 | 340 | 295 | 266 | 24 | 3 | 12-22 | ATD210/ATE270 |

Main Dimensions-PN25(25bar)

| Nominal diameter DN(mm) | Dimensions | Connection size | Actuator model | |||||||||

| L | L0 | L1 | L2 | H | D | D1 | D2 | C | f | N-D | ||

| 15 | 150 | 72 | 159/211 | 83/95 | 235/247 | 95 | 65 | 46 | 14 | 2 | 4-14 | ATD63/ATE75 |

| 20 | 160 | 80 | 211/248 | 95/107 | 252/260 | 105 | 75 | 56 | 16 | 2 | 4-14 | ATD75/ATE88 |

| 25 | 180 | 90 | 248/269 | 107/123 | 265/289 | 115 | 85 | 65 | 16 | 2 | 4-14 | ATD88/ATE100 |

| 32 | 200 | 100 | 248/315 | 107/141 | 287/312 | 140 | 100 | 76 | 18 | 3 | 4-18 | ATD88/ATE115 |

| 40 | 220 | 110 | 269/409 | 123/152 | 317/339 | 150 | 110 | 84 | 18 | 3 | 4-18 | ATD100/ATE125 |

| 50 | 240 | 120 | 345/345 | 123/152 | 325/347 | 165 | 125 | 99 | 20 | 3 | 4-18 | ATD100/ATE125 |

| 65 | 260 | 130 | 269/345 | 141/172 | 357/389 | 185 | 145 | 118 | 22 | 3 | 4-18 | ATD115/ATE145 |

| 80 | 280 | 140 | 315/438 | 152/187 | 400/425 | 200 | 160 | 132 | 24 | 3 | 8-18 | ATD125/ATE160 |

| 100 | 320 | 160 | 409/550 | 172/215 | 443/531 | 235 | 190 | 156 | 24 | 3 | 8-22 | ATD145/ATE190 |

| 125 | 400 | 190 | 438/600 | 187/240 | 548/583 | 270 | 220 | 184 | 26 | 3 | 8-26 | ATD160/ATE210 |

| 150 | 440 | 220 | 550/633 | 215/262 | 628/665 | 300 | 250 | 211 | 28 | 3 | 8-26 | ATD190/ATE240 |

| 200 | 550 | 260 | 600/730 | 210/330 | 695/744 | 360 | 310 | 274 | 30 | 3 | 12-22 | ATD210/ATE270 |

Remarks: According to different valve torques, different air source pressures and different actual working conditions, the relevant dimensions of the corresponding actuators will also change accordingly.

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333