Cryogenic Butterfly Valve

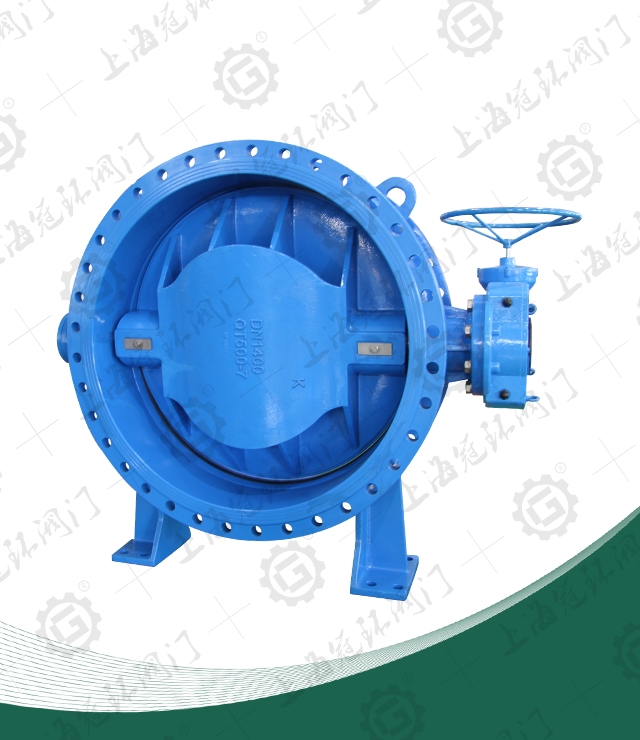

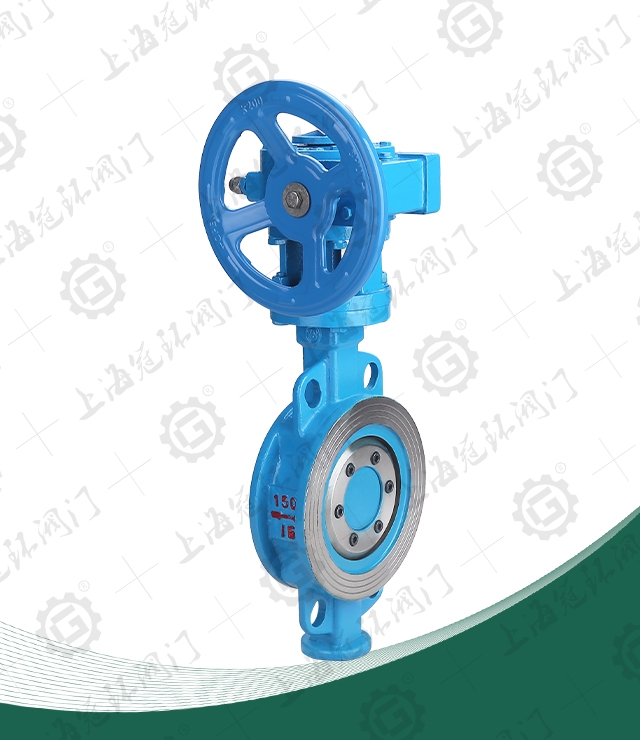

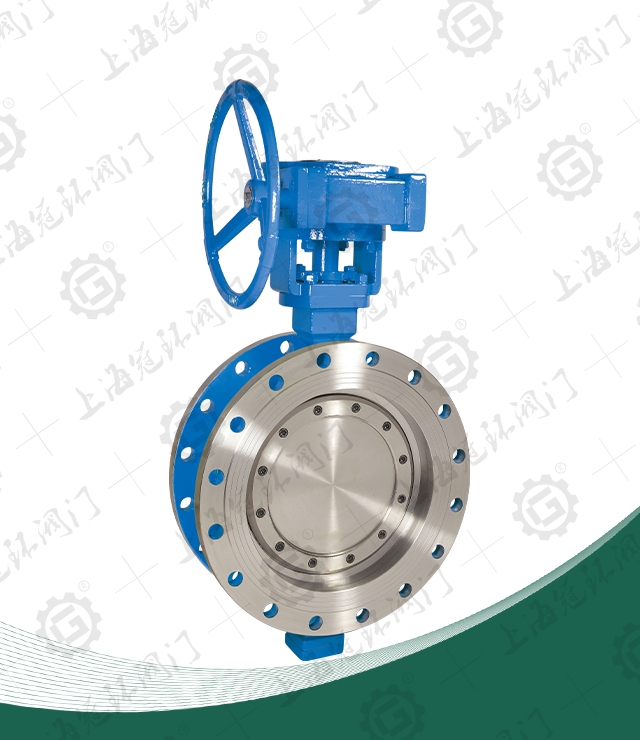

Nominal diameter: NPS 3"~NPS 48" DN80~DN1200

Pressure range: CL150~CL900 PN6~PN150

Main material: carbon steel, stainless steel, alloy steel, etc

Working temperature: ≥-196°C

Design standards: API 609, GB/T12238, JB/T 8527, GB/T 24925, BS 6364

Structure length: API 609, ASME B16.10, GB/T12221

Connection standards: ASME B16.5, ASME B16.4, GB/T 9113, HG/T 20592

Inspection and testing: API 598, GB/T13927, JB/T9092, GB/T 26480

Pressure and temperature grades: ASME B16.34, GB/T 12224

1. The double sealing of valve stem lip-seal + packing can reduce the amount of packing.

2. Extend the valve cover design, strictly control the gap between the

valve stem and the extended neck, reduce the cold flow channeling, and

prevent the filling material icing caused by the large switch torque and

the scratching of the valve stem.

3. The gland and sleeve adopt self-centering design to effectively prevent imbalance caused by uneven force on the gland.

4. Using finite element auxiliary design, the high-quality wall

thickness of the extended valve cover is obtained to ensure that the

cooling effect is better.

5. Drip board design, increase the cooling area, prevent the filling

material from freezing; Effectively avoid condensate dripping onto the

valve body.

6. The sealing surface of the valve seat is hardened to ensure that it will not be scratched at low temperature.

7. Set a drainage groove at the packing mouth of the extended valve

cover to effectively prevent condensate from entering the packing

cavity.

8. The

special cutting method of the four open rings ensures that the four

open rings form a complete ring structure after assembly, with uniform

force and better pressure-bearing effect.

9. Internal top-loading structure, convenient for online maintenance of pipelines.

10. Detachable sealing pair design, with elastic supplement function at

low temperature, lower leakage rate and better performance.

10. The fixed structure of the oblique cone pin effectively prevents

the butterfly plate from reversing under the action of pressure

difference, causing internal leakage.

12. All fasteners in contact with low temperature adopt full thread structure.

Main connection size(CLASS150)

|

DN |

A |

B |

C |

D |

L |

ΦW |

H |

|

in/mm |

|||||||

|

3(80) |

632 |

125 |

410 |

596 |

114 |

150 |

280 |

|

4(100) |

662 |

141 |

440 |

626 |

127 |

150 |

280 |

|

6(150) |

740 |

165 |

530 |

700 |

140 |

200 |

280 |

|

8(200) |

795 |

214 |

585 |

755 |

152 |

300 |

315 |

|

10(250) |

885 |

243 |

675 |

845 |

165 |

500 |

350 |

|

12(300) |

974 |

286 |

740 |

918 |

178 |

500 |

350 |

|

14(350) |

1059 |

312 |

825 |

1003 |

190 |

600 |

380 |

|

16(400) |

1115 |

350 |

845 |

1035 |

216 |

700 |

380 |

|

18(450) |

1200 |

383 |

930 |

1120 |

222 |

500 |

485 |

|

20(500) |

1200 |

414 |

930 |

1120 |

229 |

500 |

485 |

|

24(600) |

1400 |

484 |

1040 |

1260 |

267 |

600 |

538 |

|

30(750) |

1655 |

611 |

1265 |

1495 |

318 |

500 |

621 |

|

32(800) |

1655 |

611 |

1265 |

1495 |

318 |

600 |

621 |

|

36(900) |

1840 |

736 |

1450 |

1680 |

330 |

700 |

666 |

|

40(1000) |

2000 |

801 |

1580 |

1820 |

410 |

600 |

766 |

|

42(1050) |

2000 |

801 |

1580 |

1820 |

410 |

700 |

766 |

|

48(1200) |

2167 |

866 |

1717 |

1967 |

470 |

800 |

793 |

Main connection size(CLASS 300)

|

DN |

A |

B |

C |

D |

L |

ΦW |

H |

|

in/mm |

|||||||

|

3(80) |

632 |

125 |

410 |

596 |

114 |

150 |

280 |

|

4(100) |

662 |

141 |

440 |

626 |

127 |

300 |

315 |

|

6(150) |

760 |

189 |

550 |

720 |

140 |

300 |

315 |

|

8(200) |

849 |

236 |

615 |

793 |

152 |

500 |

350 |

|

10(250) |

939 |

272 |

705 |

883 |

165 |

600 |

380 |

|

12(300) |

1010 |

310 |

740 |

930 |

178 |

400 |

465 |

|

14(350) |

1115 |

335 |

845 |

1035 |

190 |

500 |

485 |

|

16(400) |

1235 |

389 |

875 |

1095 |

216 |

500 |

540 |

|

18(450) |

1370 |

422 |

1010 |

1230 |

222 |

600 |

540 |

|

20(500) |

1410 |

462 |

1050 |

1270 |

229 |

500 |

620 |

|

24(600) |

1525 |

531 |

1135 |

1365 |

267 |

600 |

660 |

|

30(750) |

1670 |

671 |

1340 |

1420 |

318 |

500 |

730 |

|

32(800) |

1850 |

671 |

1430 |

1528 |

318 |

600 |

795 |

|

36(900) |

1968 |

801 |

1564 |

1680 |

330 |

900 |

810 |

Main connection size(CLASS 600)

|

DN |

A |

B |

C |

D |

L |

ΦW |

H |

|

in/mm |

|||||||

|

4(100) |

678 |

185 |

448 |

638 |

190 |

300 |

315 |

|

6(150) |

789 |

238 |

555 |

733 |

210 |

500 |

350 |

|

8(200) |

875 |

263 |

605 |

795 |

230 |

600 |

380 |

|

10(250) |

1095 |

328 |

735 |

955 |

250 |

400 |

465 |

|

12(300) |

1178 |

365 |

788 |

1018 |

270 |

500 |

485 |

|

14(350) |

1300 |

390 |

910 |

1140 |

290 |

500 |

534 |

|

16(400) |

1370 |

440 |

980 |

1210 |

310 |

500 |

622 |

|

18(450) |

1483 |

460 |

1033 |

1283 |

330 |

500 |

622 |

|

20(500) |

1595 |

526 |

1145 |

1395 |

350 |

700 |

658 |

|

24(600) |

1685 |

623 |

1235 |

1485 |

390 |

500 |

730 |

Main connection size(CLASS 900)

|

DN |

A |

B |

C |

D |

L |

ΦW |

H |

|

in/mm |

|||||||

|

6(150) |

789 |

238 |

555 |

733 |

225 |

500 |

340 |

|

8(200) |

936 |

293 |

666 |

856 |

275 |

400 |

464 |

|

10(250) |

1130 |

345 |

770 |

990 |

325 |

400 |

464 |

|

12(300) |

1260 |

378 |

870 |

1100 |

375 |

400 |

520 |

|

14(350) |

1373 |

456 |

983 |

1213 |

425 |

500 |

623 |

|

16(400) |

1420 |

492 |

1030 |

1260 |

475 |

500 |

623 |

|

18(450) |

1510 |

510 |

1120 |

1370 |

500 |

700 |

656 |

|

20(500) |

1670 |

590 |

1220 |

1470 |

575 |

800 |

656 |

|

24(600) |

1830 |

673 |

1380 |

1630 |

675 |

700 |

793 |

Contact us

Contact us

+86-021-67895388

+86-021-67895388 shghfmc@163.com

shghfmc@163.com  93862333

93862333