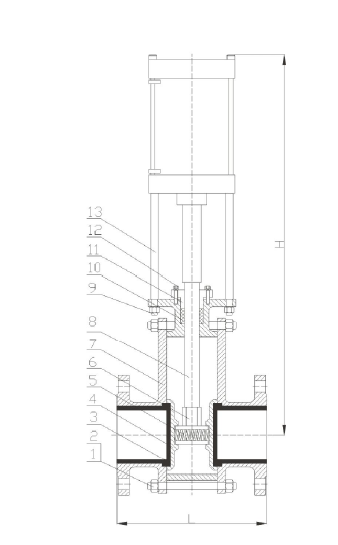

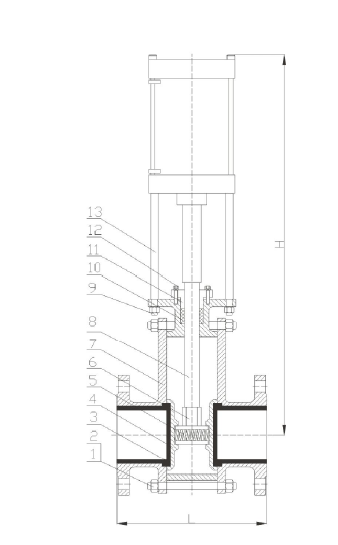

Product overview

Pneumatic

ceramic double gate valve, also known as pneumatic ceramic parallel

double gate valve or dry ash valve, is a kind of ceramic gate valve.

Therefore, its structure and working principle are consistent with the

ceramic gate valve, and its opening and closing body (valve plate) is

driven by the valve stem to the sealing surface of the valve seat for

lifting movement, which can be connected or cut off the fluid channel.

When the valve is partially opened, eddy current is generated on the

back of the gate, which is easy to cause erosion and vibration of the

gate, and it is also easy to damage the sealing surface of the seat,

which is difficult to repair. It is usually suitable for working

conditions that do not require frequent opening and closing, and keep

the gate fully open or fully closed. The ceramic track bar arranged on

the inside of the valve cover and the power spring arranged in the

three-way valve core can effectively make the left and right gate plate

move closely on the ceramic track bar without any leakage, so as to

ensure the normal operation of the valve body. The utility model has

simple structure and convenient installation and use.

Ceramic

double gate valve is mainly used for dry powder material inlet,

discharging and conveying pipeline, as a cut-off and connecting medium

channel, as a warehouse pump discharge valve, balance valve, exhaust

valve, blockage valve, can also be used as a pipeline switching valve

and ash warehouse discharge valve, with good sealing performance, small

starting load, less ash and ash accumulation phenomenon, wear

resistance, long service life characteristics. Ceramic double gate

valves are usually connected by flanges and can be divided into manual

and electric drive modes. Specifically, the range of use of this series

of products is: 1. Power plant ash removal - dry ash removal system; 2.

Selection and transportation of dry ore powder materials in

concentrator; 3. Cement industry - dry powder conveying and discharging;

4. Flour mill - flour conveying pipeline. 5. Other powder or small

solid particles and other high-wear media transportation, because these

mining media often have hard particles and fibrous dirt and other

objects, the valve in the pipeline system as a opening and closing

device, can play an excellent role.

Product characteristics

1.

The valve has advanced design concept, which has incomparable

characteristics of ordinary valves. As a fluid control system, it

effectively solves the long-unsolved phenomenon of gate valve sealing

surface damage and leakage caused by debris.

2.

The valve adopts a spring self-sealing structure and a special sealing

surface, so that the sealing pair is always consistent at any position,

and the residual dirt (such as sediment, welding slag and other

attachments) bonded on the sealing surface can be thoroughly scraped

off. The sealing surface is not damaged. It has been proved by many

manufacturers that the structure can not only scrape all kinds of dirt

on the sealing surface, but also cut off the stainless steel welding rod

of Phi 5mm, and the sealing surface is not damaged at all, and it works

normally.

3.

Because the self-sealing structure of the spring in the valve can

automatically compensate for the normal wear of the sealing surface, on

the one hand, the leakage rate is zero due to the strong sealing, on the

other hand, the working life of the valve is greatly improved, and the

cost is saved for the enterprise.

4.

The valve adopts a wedge roller type switch mechanism, which can switch

the valve easily and make up the warning device of a small amount of

leakage on the sealing surface. If there is a small leak in the valve,

as long as the hand wheel is closed, the valve can keep zero leakage,

and ordinary valves do not have this skill.

5.

Due to the use of special switching mechanism, to prevent the ordinary

gate due to large temperature changes, so that the gate plate stuck, and

can not open the phenomenon.

6.

The valve is equipped with an automatic blowdown system at the bottom,

which always keeps the body cavity clean and no residue.

7.

The valve body is provided with a dust-proof mechanism to ensure that

there will be no dirt immersion in the valve cavity, and the internal

mechanism will fail